The manufacturing industry is continuously evolving, with foundries constantly evaluating more efficient, cost-effective, and precise methods for metal casting. One process that frequently enters this discussion is Lost Foam Casting (LFC). The central question remains: can this innovative technique truly replace long-established traditional methods like green sand casting or investment casting? This article examines the key aspects of Lost Foam Casting to provide a balanced perspective.

Understanding Lost Foam Casting

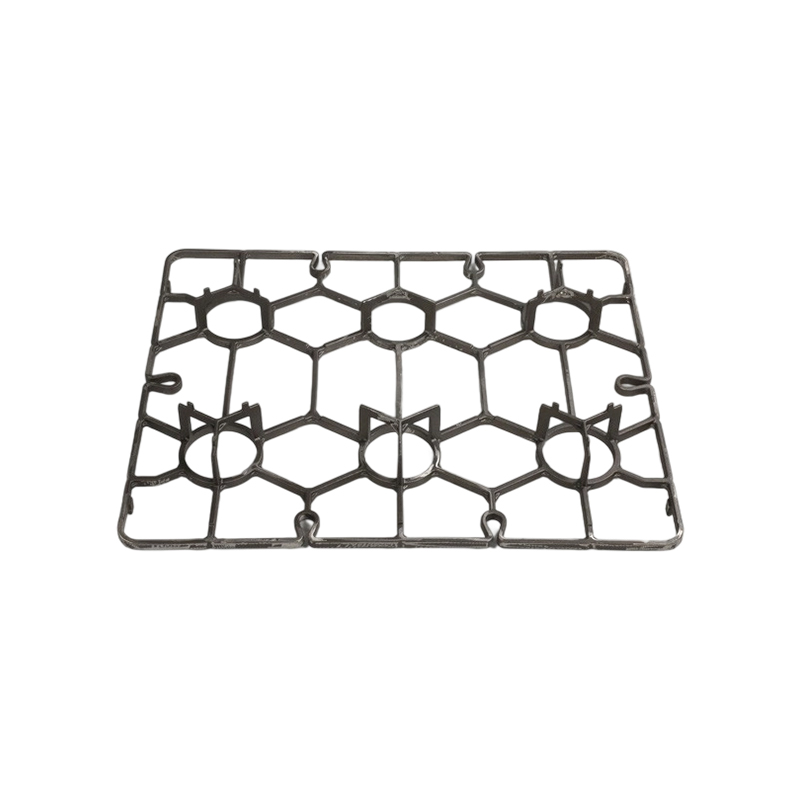

Lost Foam Casting is a process where a pattern made of expandable polystyrene (EPS) or copolymer foam is embedded in unbonded sand. Molten metal is poured directly into the pattern, which vaporizes upon contact, being replaced precisely by the metal. This method eliminates the need for cores and binders used in conventional sand casting, simplifying the mold-making process.

Comparative Advantages of Lost Foam Casting

The potential of Lost Foam Casting to compete with traditional methods lies in its distinct advantages:

-

Design Flexibility: LFC allows for the production of highly complex, intricate geometries that would be difficult or impossible to achieve with traditional sand casting without numerous cores. This includes internal passages and undercuts.

-

Dimensional Accuracy and Surface Finish: Components produced via Lost Foam Casting typically exhibit excellent dimensional accuracy and a superior surface finish compared to most green sand castings, often reducing the need for extensive secondary machining.

-

Process Simplification: The absence of cores, binders, and parting lines streamlines the molding process. This consolidation of steps can lead to reduced labor costs and lower energy consumption.

-

Material Efficiency: The near-net-shape capability of LFC minimizes metal waste in the form of sprues, risers, and machining scrap, contributing to its cost-effectiveness for certain applications.

Limitations and Challenges

Despite its benefits, Lost Foam Casting is not a universal replacement. Its limitations must be carefully considered:

-

Pattern Cost: The initial cost of creating a precise foam pattern, often using specialized molding equipment, can be high. This makes LFC less economical for very low-volume production runs compared to simple sand casting.

-

Material and Process Control: The process is highly sensitive. The foam pattern quality, coating applied to the pattern, and sand compaction must be meticulously controlled to avoid defects such as folds or carbon inclusions.

-

Alloy Restrictions: While suitable for a wide range of metals, including iron, steel, and aluminum, the process can present challenges with certain alloys that are highly reactive or require very high pouring temperatures.

-

Production Rate: For very high-volume, simple parts, highly automated green sand lines can often achieve faster cycle times than Lost Foam Casting systems.

Application-Based Suitability

The question of replacement is not binary but application-specific. Lost Foam Casting has proven to be a superior choice in several sectors:

-

Automotive Industry: For complex engine components like cylinder heads, intake manifolds, and brake calipers, where weight reduction and internal complexity are critical.

-

Pump and Valve Manufacturing: For parts with intricate internal waterways and chambers.

-

Heavy Machinery: For large, complex castings that benefit from the process's ability to consolidate multiple parts into a single casting.

Rather than a full-scale replacement, Lost Foam Casting is best viewed as a powerful alternative within the foundry's toolkit. It occupies a specific niche, excelling in applications demanding high complexity, excellent surface finish, and reduced machining. For high-volume production of simpler geometries, traditional green sand casting remains highly efficient and cost-effective. For small, highly precise parts requiring the finest detail, investment casting may still be preferred.

The decision to adopt Lost Foam Casting must be based on a thorough analysis of the part design, production volume, required quality, and total cost. As pattern-making technologies improve and process control becomes more advanced, the range of applications for LFC is likely to expand. However, its role will continue to be complementary to, rather than a wholesale replacement for, well-established traditional casting methods.

English

English русский

русский Español

Español عربى

عربى