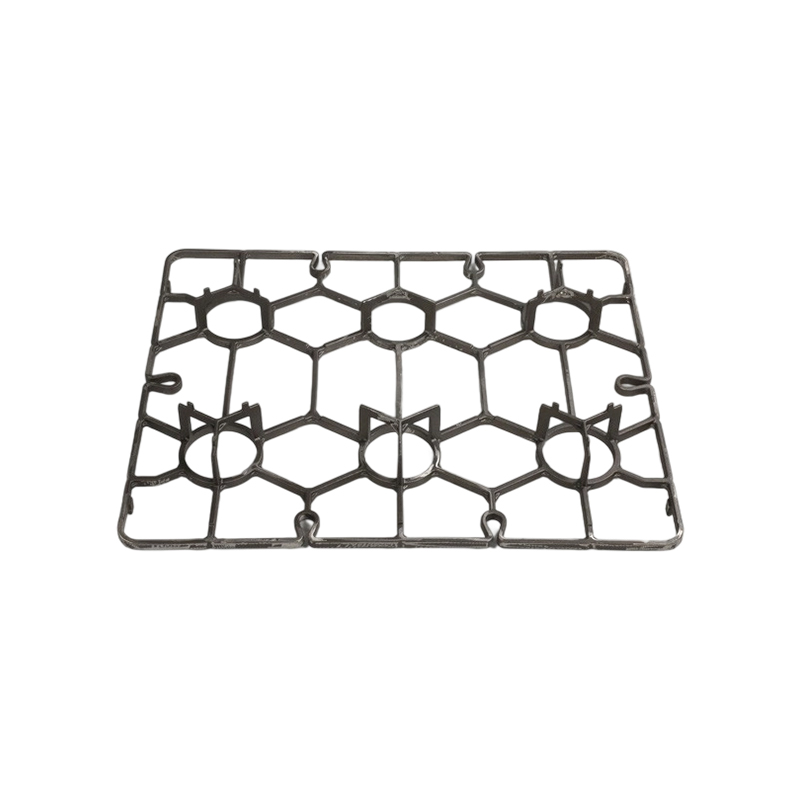

Lost Foam Casting (LFC), also known as the evaporative pattern casting process, offers distinct advantages for producing complex, near-net-shape metal components. Its unique process – using a foam pattern vaporized by molten metal within unbonded sand – makes it particularly suitable for specific applications across key industries.

-

Automotive Industry (The Dominant Sector):

-

Engine Components: This is arguably the largest application area. LFC excels at producing intricate internal passages found in aluminum cylinder heads, engine blocks (particularly V-configurations), and intake manifolds. The ability to create complex water jackets, oil galleries, and intake runners without traditional cores significantly reduces complexity and machining costs. Ductile iron exhaust manifolds are also frequently produced via LFC due to their complex shapes and need for good surface finish.

-

Transmission Components: Complex housings and cases, often made from aluminum, benefit from LFC's ability to integrate internal features and reduce weight while maintaining structural integrity.

-

Brake Components: Certain brake system parts like calipers and brackets leverage the process for dimensional accuracy and intricate geometries.

-

-

Heavy Machinery and Equipment:

-

Pump Housings and Impellers: The complex internal volutes and vanes required for pumps (water, chemical, slurry) are ideally suited to LFC. It allows for smooth internal surfaces and integrated features difficult to achieve with conventional sand casting.

-

Valve Bodies: Industrial valves, especially those requiring complex internal flow paths, intricate porting, or corrosion-resistant alloys, are strong candidates for LFC.

-

Construction & Agricultural Equipment Parts: Components like hydraulic valve bodies, gearbox casings, and structural elements requiring internal cavities or complex shapes are commonly produced using this method.

-

-

Valve and Pump Manufacturing (Specialized Focus):

-

Beyond heavy machinery, dedicated valve and pump manufacturers heavily utilize LFC for a wide range of products, particularly in sizes ranging from a few pounds to several hundred pounds. The process is valued for its ability to handle alloys like stainless steels, duplex steels, and nickel alloys often required for corrosion resistance, while achieving the necessary internal geometries.

-

-

General Engineering Components:

-

LFC is employed for various parts requiring complex internal cavities, near-net-shape dimensions, or excellent surface finish. Examples include:

-

Complex brackets and levers with internal strengthening ribs.

-

Housings for machinery requiring integrated channels or mounting points.

-

Components where core assembly for conventional casting would be prohibitively complex or expensive.

-

-

Key Drivers for LFC Adoption in These Areas:

-

Complex Internal Geometries: The single-piece foam pattern allows for shapes impossible or extremely costly to core using traditional sand methods (e.g., undercuts, intersecting passages, complex curves). This is its primary advantage.

-

Reduced Machining: Near-net-shape capability significantly cuts down on machining time, tool wear, and material waste, leading to cost savings, especially for complex parts.

-

Consolidation of Parts: LFC often allows multiple components to be cast as a single piece, eliminating assembly steps and potential leak paths.

-

Good Surface Finish: Typically superior to conventional green sand casting, reducing cleaning and finishing requirements.

-

Dimensional Accuracy: Generally good dimensional consistency and repeatability.

-

Alloy Flexibility: Suitable for a wide range of ferrous (cast iron, ductile iron, steel) and non-ferrous (aluminum, bronze, brass) alloys.

Important Considerations:

-

Pattern Cost & Lead Time: Creating the precision foam pattern (usually via CNC machining of a tool or directly machining foam) requires upfront investment and time. Economic viability is often tied to sufficient production volume.

-

Size Limitations: While capable of large castings, practical limitations exist based on foam handling and mold filling dynamics, typically favoring parts from a few ounces up to several hundred pounds, though larger are possible.

-

Process Control: Requires strict control over pattern quality, coating application, sand compaction, and pouring parameters to prevent defects like folds or carbon inclusions.

Lost Foam Casting finds its strongest foothold in industries demanding high geometric complexity, particularly involving intricate internal features, where its ability to eliminate traditional cores provides a significant manufacturing advantage. The automotive sector remains the largest consumer, especially for critical engine and transmission components. Heavy machinery, specialized valve/pump manufacturing, and general engineering applications requiring complex near-net-shape parts also represent core application areas. The decision to use LFC hinges on balancing the benefits of geometric freedom and reduced machining against the costs and lead times associated with pattern production for a given component and volume.

English

English русский

русский Español

Español عربى

عربى