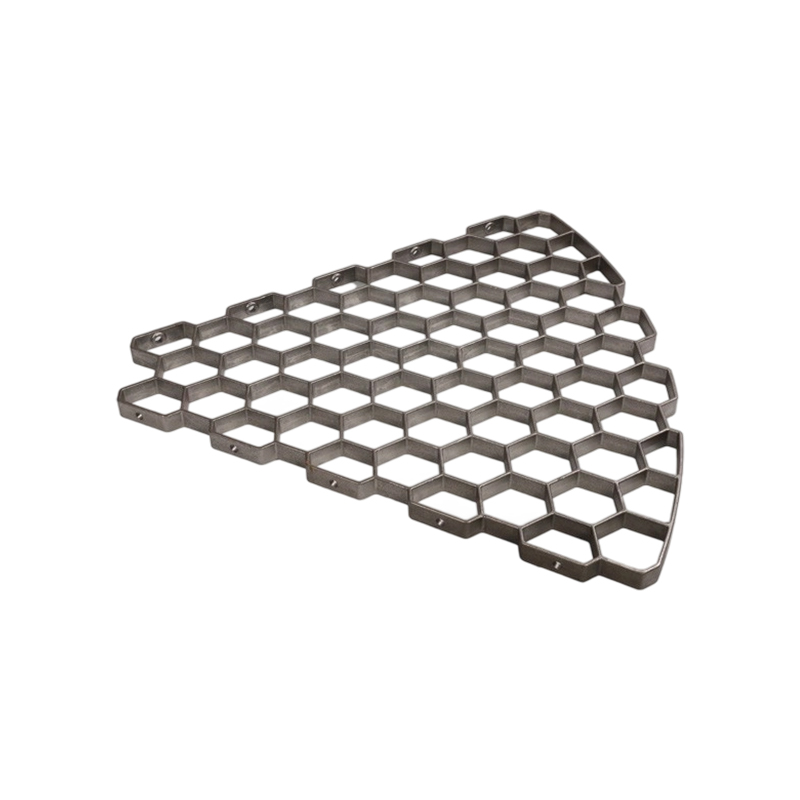

Heat Treatment Tray is an essential piece of equipment used in various industries to withstand extreme temperatures during heat treatment processes. These trays are designed to hold and organize metal or other materials undergoing high-temperature treatments such as annealing, quenching, or tempering. The ability of a heat treatment tray to resist heat is critical to maintaining the integrity of the materials and ensuring the efficiency of the treatment process.

- 1 What is Heat Treatment?

- 2 Factors Influencing Heat Resistance of Heat Treatment Trays

- 3 Common Materials Used for Heat Treatment Trays

- 4 Heat Resistance in Different Industrial Applications

- 5 Why Heat Treatment Tray Durability is Important

- 6 How Do Heat Treatment Trays Compare to Other Heat-Resistant Equipment?

- 7 FAQ: Heat Treatment Tray Performance

- 8 Conclusion

What is Heat Treatment?

Heat treatment refers to the process of heating and cooling materials, primarily metals, to alter their physical and mechanical properties without changing the material's shape. The process is used to improve hardness, durability, strength, and resistance to wear. Heat treatment trays are used to carry items through different stages of this process, ensuring that the items are not damaged by extreme temperatures.

Factors Influencing Heat Resistance of Heat Treatment Trays

Several factors determine how effectively a Heat Treatment Tray can withstand high temperatures:

- Material Composition: The tray's ability to withstand high temperatures is primarily dependent on the materials used in its construction. High-grade stainless steel, titanium, and special alloys are commonly used for their superior heat resistance properties.

- Thermal Conductivity: The material's thermal conductivity plays a role in how quickly heat spreads through the tray. Materials with low thermal conductivity tend to resist heat better, preventing the tray from deforming or failing under extreme conditions.

- Design and Structure: The structural integrity of the tray is crucial for its ability to handle high temperatures. Features such as reinforcement ribs, support structures, and even surface coatings can enhance the tray’s durability.

Common Materials Used for Heat Treatment Trays

The materials chosen for Heat Treatment Trays are critical for ensuring longevity and performance in high-temperature environments. Some commonly used materials include:

| Material | Properties | Best Use |

|---|---|---|

| Stainless Steel | Excellent resistance to oxidation and corrosion; high tensile strength at elevated temperatures. | Ideal for general heat treatment applications and industries requiring high strength and corrosion resistance. |

| Titanium | Exceptional heat resistance and strength; lightweight and corrosion-resistant. | Used in industries such as aerospace and medical devices where high-temperature performance is critical. |

| Inconel | Superalloy with high-temperature strength and oxidation resistance. | Commonly used in industries with extreme heat environments, such as gas turbines and rocket engines. |

| Graphite | Excellent resistance to heat and wear; used for applications requiring high thermal stability. | Used in high-temperature furnaces and environments where traditional metals might fail. |

Heat Resistance in Different Industrial Applications

Heat Treatment Trays are used in a variety of industries, and the ability to withstand high temperatures is crucial in each case. Below are some examples of how these trays are used across different sectors:

- Aerospace Industry: Heat treatment trays are used in the aerospace industry to treat metals used in aircraft engines. The high temperatures required to harden engine components like turbine blades make heat-resistant trays essential.

- Automotive Manufacturing: In automotive manufacturing, heat treatment trays hold engine parts, suspension components, and transmission elements during heat treatment processes to improve their mechanical properties.

- Foundries and Metalworking: Trays are used to hold molten metal or castings as they are heat-treated to improve strength, hardness, and durability.

- Electronics: Certain high-performance electronics require heat treatment to improve their properties. Specialized trays are used in these processes to prevent overheating and maintain quality.

Why Heat Treatment Tray Durability is Important

The durability of heat treatment trays plays a significant role in ensuring the success of heat treatment operations. If a tray deforms or fails under heat stress, it can result in damage to the workpieces or inefficiency in the treatment process. Additionally, tray failures can cause costly downtime and increase the risk of accidents, which can negatively impact production timelines and safety standards.

How Do Heat Treatment Trays Compare to Other Heat-Resistant Equipment?

Compared to other heat-resistant equipment such as furnaces or kilns, heat treatment trays are designed with specific characteristics to handle thermal stress and ensure safe transport of materials during the heat treatment process. Let's compare heat treatment trays with other common heat-resistant equipment:

| Feature | Heat Treatment Tray | Furnace | Heat Shield |

|---|---|---|---|

| Temperature Range | Typically withstands temperatures up to 1000°C-1200°C | Can handle higher temperatures, generally up to 1600°C or more | Designed for specific high-temperature protection, usually up to 1200°C |

| Material Handling | Holds workpieces during treatment without direct contact with high heat | Directly exposes materials to high temperatures for uniform heating | Provides surface protection but does not hold materials |

| Flexibility | Can be customized in size and shape to fit different items | Fixed setup, not customizable | Fixed design, used primarily for shielding specific items |

FAQ: Heat Treatment Tray Performance

1. What is the maximum temperature a heat treatment tray can withstand?

The maximum temperature a Heat Treatment Tray can withstand depends on the material used in its construction. Trays made from stainless steel can typically withstand temperatures up to 1100°C, while superalloys like Inconel can endure temperatures up to 1300°C and beyond.

2. How do heat treatment trays affect the heat treatment process?

Heat treatment trays are essential for ensuring that workpieces remain properly positioned and evenly exposed to heat during the process. Their ability to withstand high temperatures prevents deformities, ensures safety, and enhances the overall efficiency of heat treatment operations.

3. Can heat treatment trays be reused after several cycles?

Yes, heat treatment trays can often be reused multiple times, but their longevity depends on factors such as material quality, design, and the specific temperatures they are subjected to during each cycle. Regular inspections are needed to ensure they are still performing optimally.

4. How do I choose the right heat treatment tray for my industry?

Choosing the right Heat Treatment Tray involves considering factors such as the temperature range, material compatibility, and load capacity required for your specific application. It's essential to select trays made from materials that match the temperature requirements and handling needs of your industry.

Conclusion

Heat Treatment Trays are indispensable tools in many industries that require high-temperature processes. Their ability to withstand extreme conditions is vital for maintaining the quality and safety of the materials being treated. By selecting the right materials and designs, companies can ensure that their heat treatment trays perform efficiently and last for extended periods, minimizing downtime and enhancing productivity.

English

English русский

русский Español

Español عربى

عربى