Heat Treatment Tray plays a pivotal role in achieving uniform heat distribution during various heat treatment processes, such as annealing, tempering, and quenching. The design of the tray influences the efficiency and uniformity of heat transfer, directly affecting the quality of the final product.

Factors Affecting Heat Distribution in Heat Treatment Trays

When designing a Heat Treatment Tray, several key factors influence the evenness of heat distribution. These factors include material properties, tray geometry, airflow, and thermal conductivity. Below, we explore how each element affects heat distribution:

- Material Composition: The material from which the tray is made can either enhance or hinder heat conduction. For example, trays made from metals like aluminum or steel generally offer better heat conduction than those made from ceramic or plastic.

- Tray Geometry: The shape and size of the tray are critical. A tray with optimal dimensions and spacing between parts allows for better airflow, ensuring that heat is distributed uniformly across all components. Trays that are too small or too large may result in localized temperature variations.

- Airflow: Proper airflow is essential for maintaining consistent temperatures. Trays with larger openings or perforations allow for more effective air circulation, leading to more uniform heating.

- Thermal Conductivity: The conductivity of the materials used for the tray significantly influences how heat spreads from one area to another. Materials with higher thermal conductivity promote more even heat distribution.

Comparing Different Heat Treatment Tray Designs

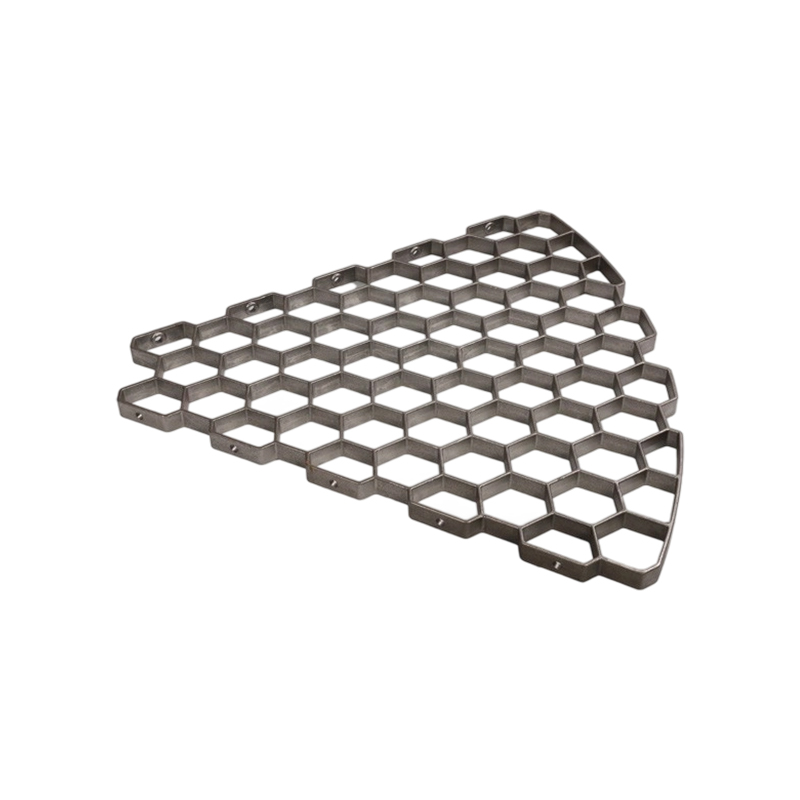

Various Heat Treatment Tray designs offer different levels of heat distribution efficiency. Let’s examine the pros and cons of some common tray designs:

| Tray Design | Advantages | Disadvantages |

|---|---|---|

| Open-Grid Tray | Improved airflow and heat distribution due to open grid structure; suitable for large components. | Can be less effective in high-temperature processes due to lower thermal conductivity. |

| Solid Plate Tray | Higher heat retention and thermal conductivity; ideal for processes requiring precise temperature control. | Poor airflow, leading to potential hot spots; may not be ideal for larger batches. |

| Perforated Tray | Balanced heat distribution with good airflow; effective for moderate heat treatment processes. | Can lead to uneven heat distribution in thicker or larger components. |

Optimizing Heat Distribution in Heat Treatment Trays

To achieve optimal heat distribution in a Heat Treatment Tray, manufacturers must consider several key practices:

- Tray Material Selection: Choose materials with high thermal conductivity for consistent heat transfer. Materials like aluminum or stainless steel are often ideal for their efficient thermal properties.

- Proper Spacing: Ensure components are placed with enough space between them to allow for effective airflow. Overcrowding can cause uneven heat distribution.

- Optimized Tray Design: Select a tray design that allows for proper air circulation while also promoting even heat conduction. Open-grid and perforated trays are good choices for maximizing airflow.

- Temperature Monitoring: Utilize temperature sensors in key areas of the tray to monitor heat distribution and make adjustments as needed during the heat treatment process.

FAQ

What is the best material for a Heat Treatment Tray?

Aluminum and stainless steel are generally considered the best materials due to their excellent thermal conductivity. They ensure uniform heat distribution during the heat treatment process.

How does the tray size affect heat distribution?

A larger tray allows for more space for components, which can improve heat distribution. However, excessively large trays can lead to inefficiency in heat retention, while smaller trays may cause localized overheating.

Why is airflow important in Heat Treatment Trays?

Airflow is essential because it helps maintain uniform temperature across the tray. Without adequate airflow, certain areas of the tray can become hotter than others, leading to inconsistent heat treatment.

Conclusion

The design of a Heat Treatment Tray is crucial for ensuring even heat distribution during heat treatment processes. Factors such as material, geometry, and airflow play significant roles in achieving thermal uniformity. By optimizing these elements, manufacturers can improve the quality of their heat-treated components and enhance production efficiency.

English

English русский

русский Español

Español عربى

عربى