Product Categories

About Us

Xinghua Jinniu Machinery Manufacturing Co., Ltd.

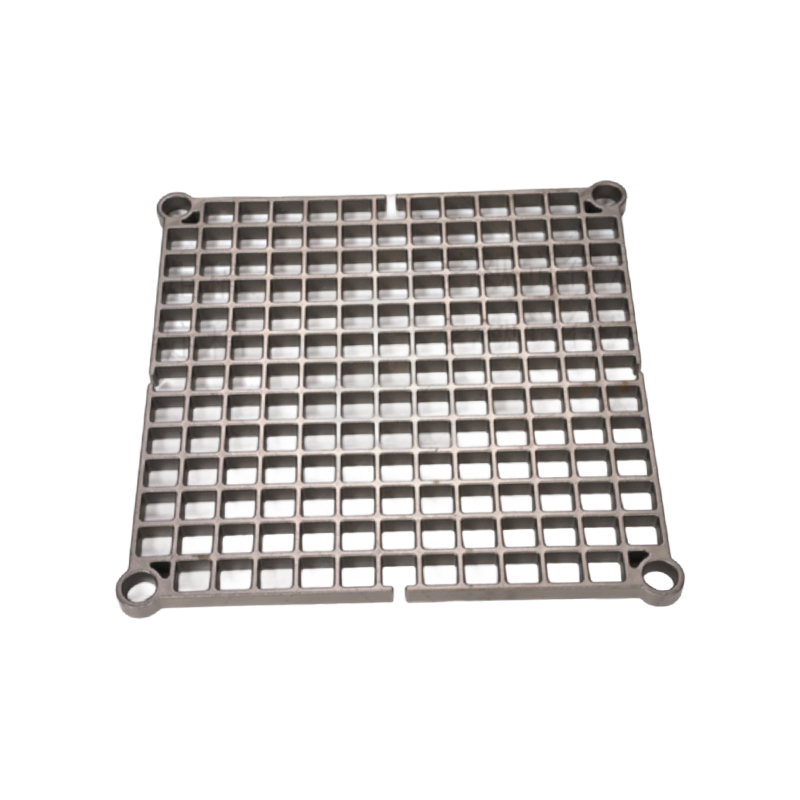

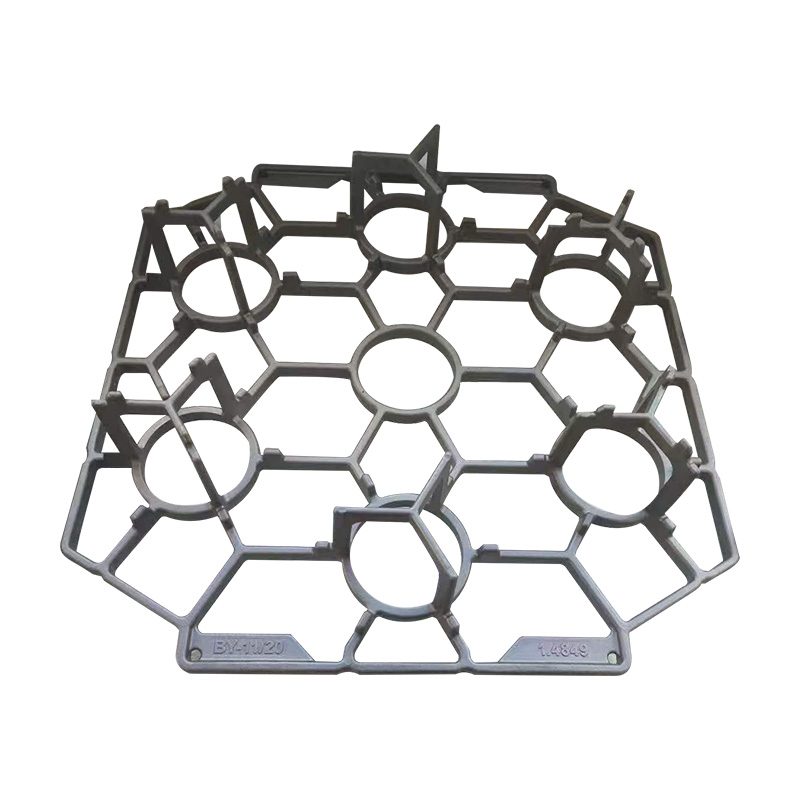

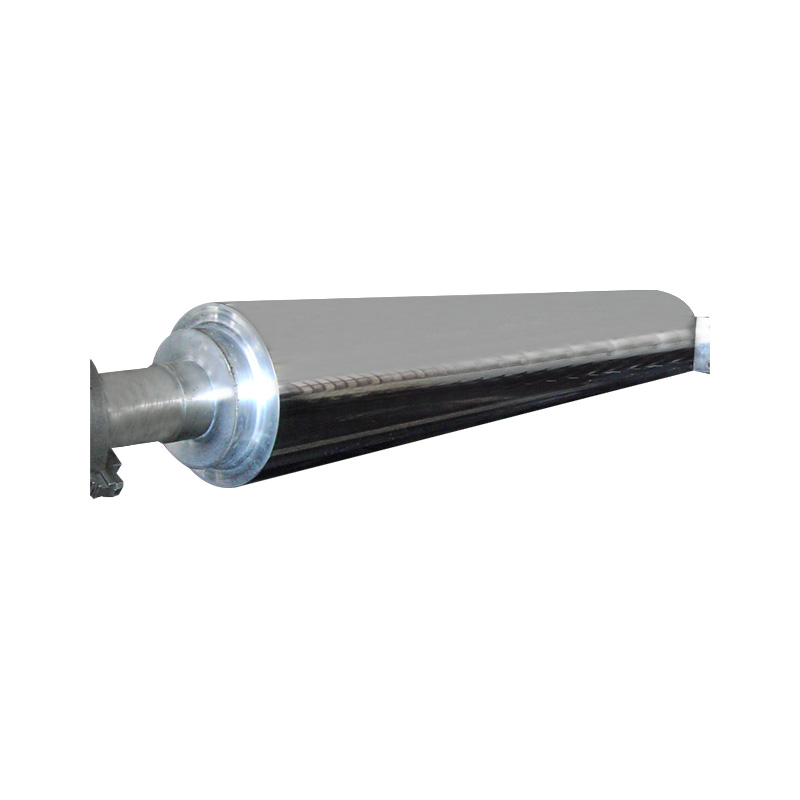

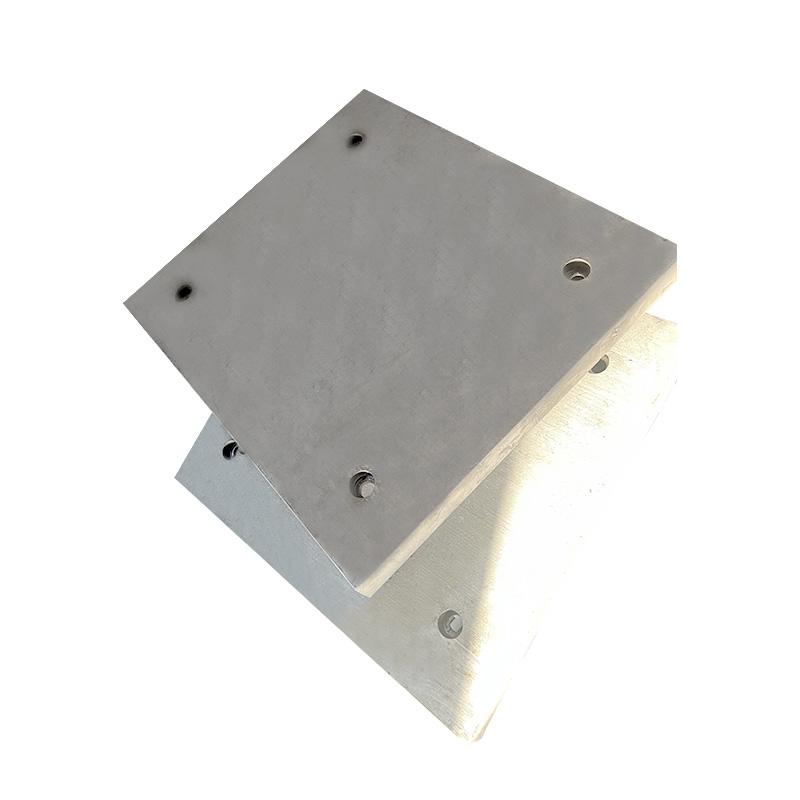

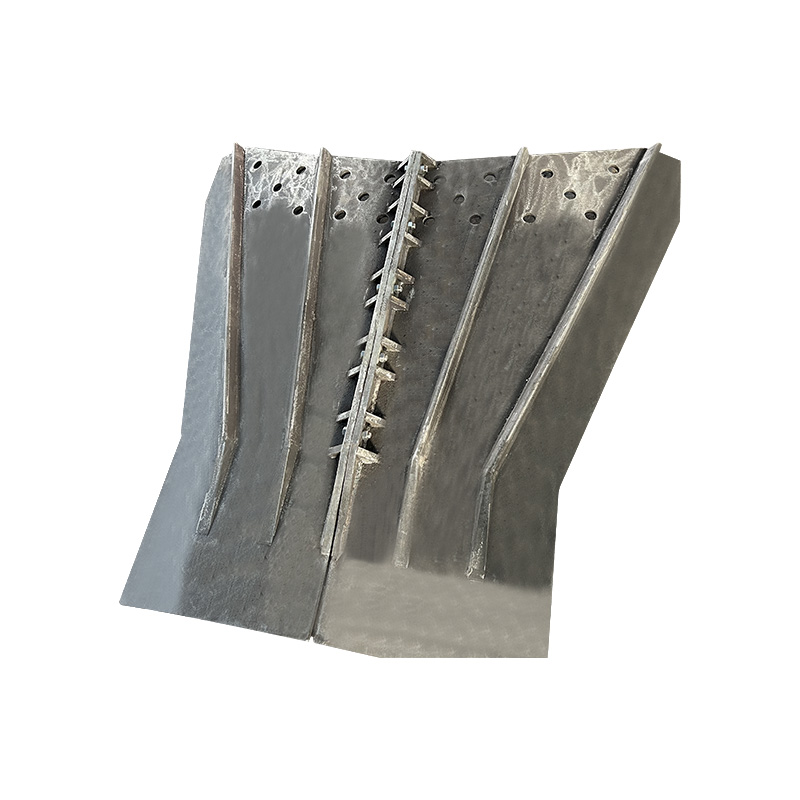

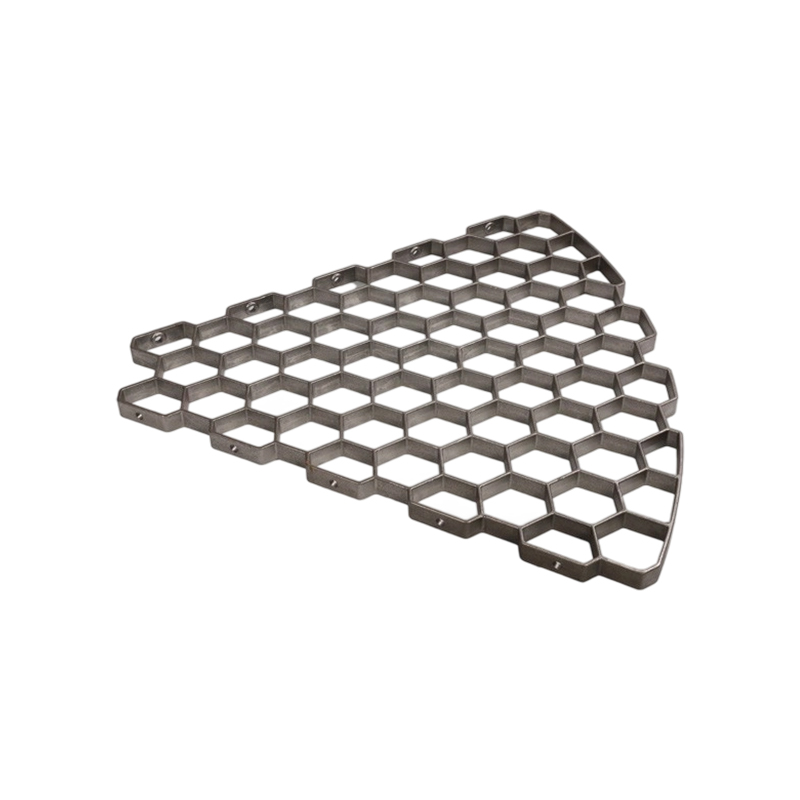

Xinghua Jinniu Machinery Manufacturing Co., Ltd. is China Lost Wax Precision Casting Stacking Fixture Factory and China Lost Wax Precision Casting Stacking Fixture OEM/ODM Company, specializes in producing various heat-resistant, wear-resistant, corrosion-resistant, nickel saving and other super strong alloy steel products, widely used in metallurgy, the chemical industry, heat treatment, new cement dry normal, pellet, garbage incineration and other production lines. We have also developed and researched various heat-resistant steel new material products at the advanced domestic level.

Our company provides high-quality heat-resistant steel products to nearly 500 enterprises all year round. It has reasonably modified some users' equipment defects to ensure their normal operation, energy saving and consumption reduction. We have gained the trust and praise of our customers.

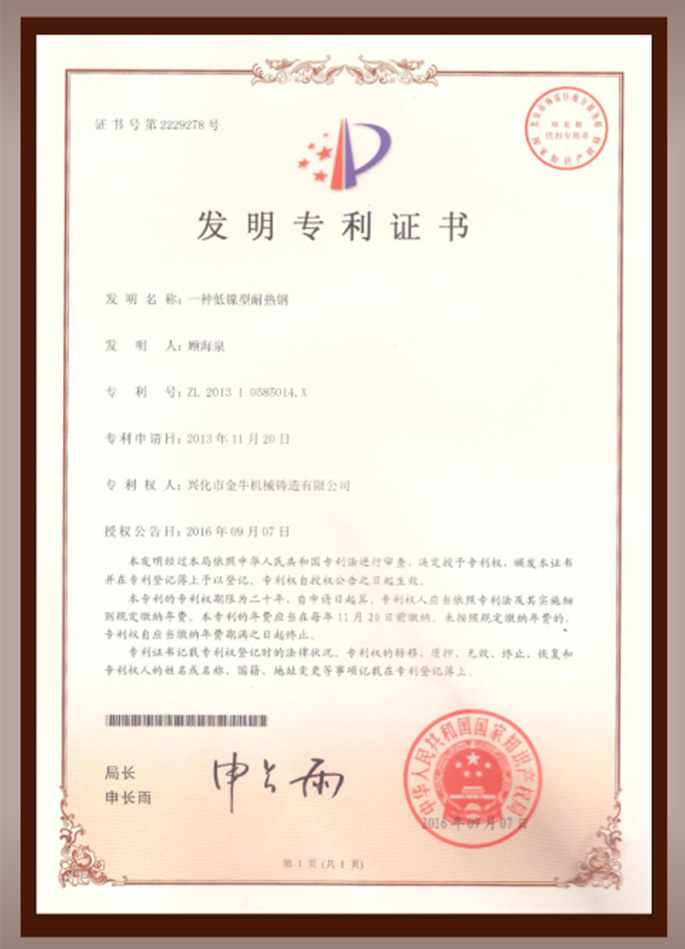

Our company has a registered capital of 21.88 million yuan and a factory area of 23100 square meters, including 5 standard production plants totaling 12000 square meters. The company has 186 employees, including 6 senior engineers, 18 intermediate technical personnel, and 28 marketing personnel. The enterprise has advanced production equipment and technology, strong technical strength, complete testing projects, and a one-stop production capacity from research and development, lost foam casting, coated sand casting, silica sol wax loss precision casting, heat treatment, forging and precision processing. Currently, it has an annual production capacity of 6000-8000 tons of high-quality heat-resistant steel and an annual sales revenue of 180 million RMB. Our company actively promotes modern enterprise management systems, continuously strengthens internal management with quality and cost as the main line, and has successfully passed ISO9001:2015 international quality management system certification and ISO14001:2015 environmental management system certification.

News

-

In modern industrial manufacturing, precision and reliability during high-temperature processing are essential. Whether used in automotive components, aerospace parts, tool manufacturing, or metallurgy, selecting the right tray fo...

READ MORE -

Heat Treatment Tray plays a pivotal role in achieving uniform heat distribution during various heat treatment processes, such as annealing, tempering, and quenching. The design of the tray influences the efficiency and uniformity ...

READ MORE -

Heat treatment trays are essential tools used in various industrial processes, especially in heat treatment applications for metals, ceramics, and other materials. These trays are designed to withstand high temperatures, but their...

READ MORE

Message Feedback

English

English русский

русский Español

Español عربى

عربى