- The casting system and riser have virtually no metal consumption, which increases the productivity of the process.

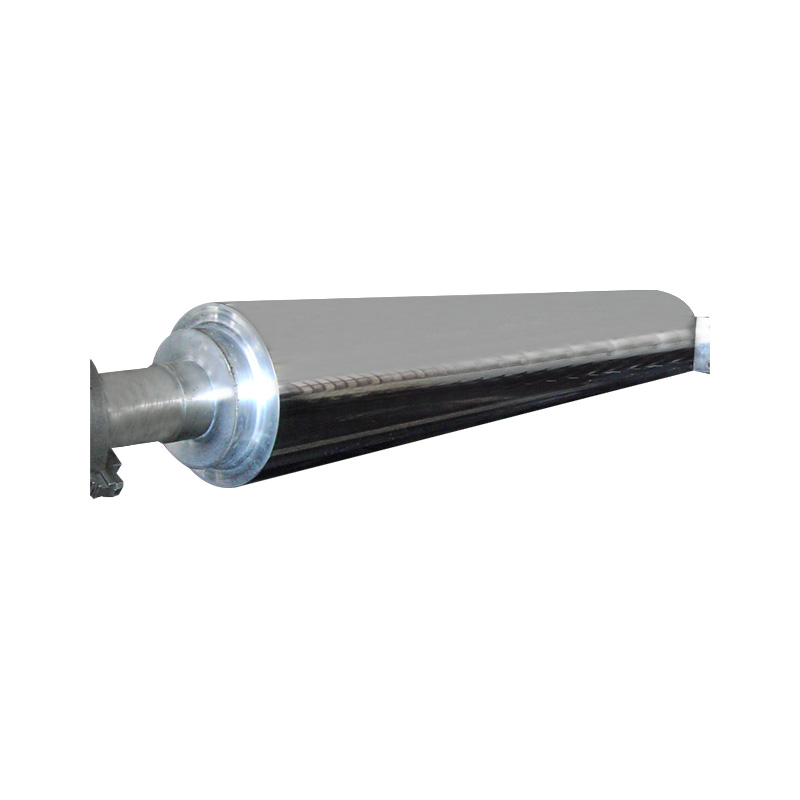

- No core is required for the production of hollow castings, so the metal filling can be significantly improved when producing long tubular castings.

- Centrifugal casting allows for the production of parts with high molding accuracy and surface quality, since the gravity of the liquid metal during centrifugal casting is converted into equivalent gravity under the action of centrifugal force, which makes the metal flow smoother, reduces deformation when cooled and increases the size and shape of the part. details are more precise.

Centrifugal casting

Centrifugal casting is a casting process that uses centrifugal force to inject molten metal into a mold, and is suitable for producing tubular and symmetrical metal parts. This process has density and uniformity, can effectively eliminate pores and inclusions in castings, and improves the strength and durability of the material. Centrifugal casting is widely used in aerospace, automobile, machinery, pipeline and other fields, and is suitable for high-demand engineering applications.

View more-

In modern industrial manufacturing, precision and reliability during high-temperature processing are essential. Whether used in automotive components, aerospace...

READ MORE -

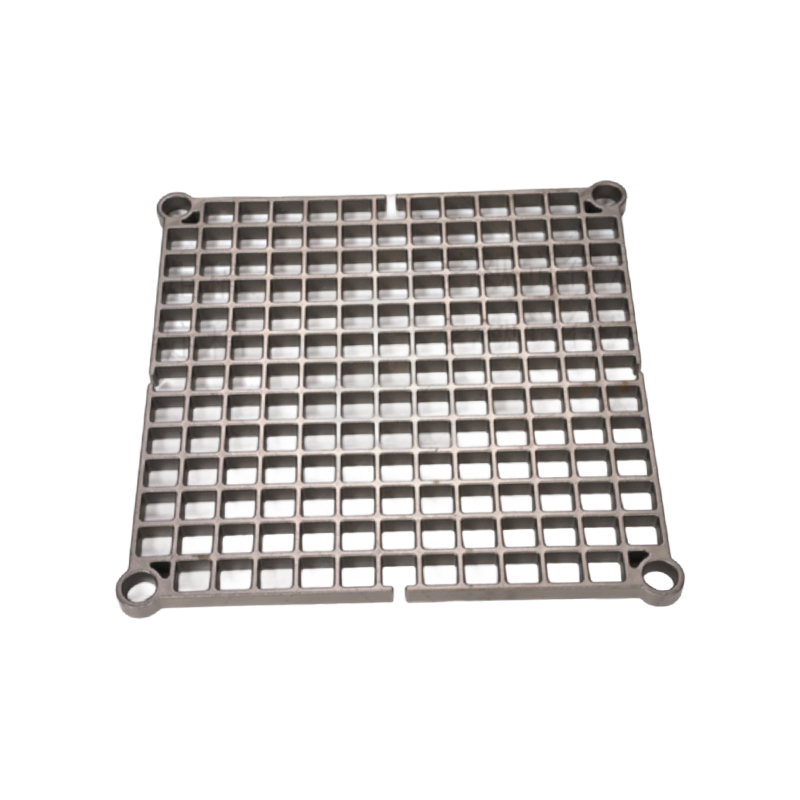

Heat Treatment Tray plays a pivotal role in achieving uniform heat distribution during various heat treatment processes, such as annealing, tempering, and quenc...

READ MORE -

Heat treatment trays are essential tools used in various industrial processes, especially in heat treatment applications for metals, ceramics, and other materia...

READ MORE -

Heat Treatment Tray is an essential piece of equipment used in various industries to withstand extreme temperatures during heat treatment processes. These trays...

READ MORE

What are the applications of Industrial Centrifugal Casting in heavy industry?

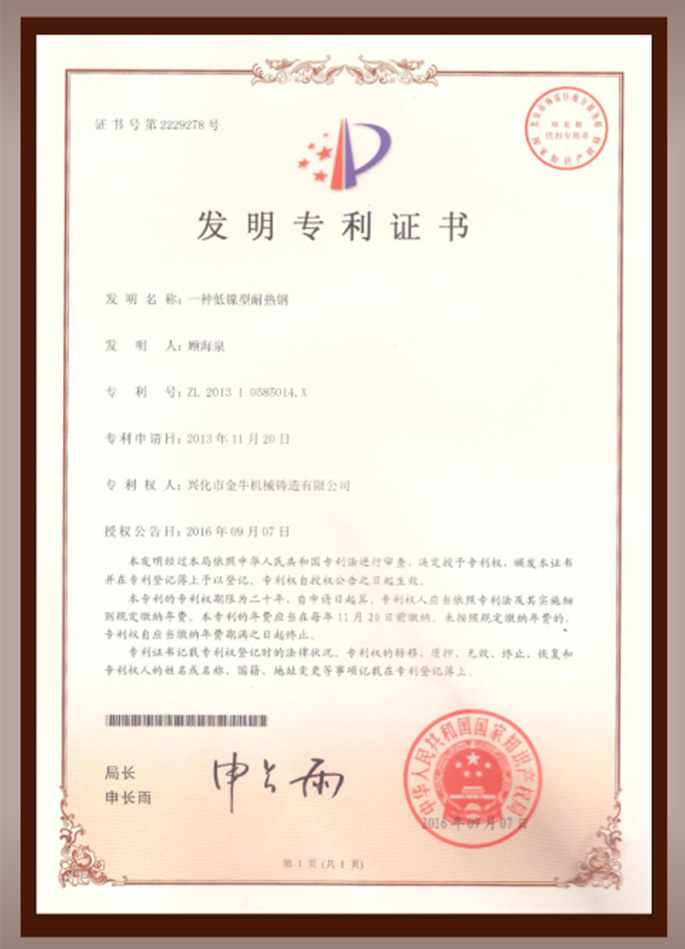

In heavy industry, Industrial Centrifugal Casting has become an important technology for manufacturing high-performance castings due to its unique advantages. This process distributes molten metal evenly into the mold through high-speed rotation, which can not only improve the density and quality of the casting, but also significantly improve the internal structure and surface finish of the casting. As one of the main casting methods of Xinghua Jinniu Machinery Manufacturing Co., Ltd., centrifugal casting is widely used in many industries, especially in heavy industries such as metallurgy, chemical industry and heat treatment.

In the field of metallurgy, Industrial Centrifugal Casting can produce high-strength castings, which are usually required to withstand high temperature, high pressure and severe wear. Xinghua Jinniu focuses on the production of alloy steel products that are resistant to high temperature, wear and corrosion, meeting the demanding requirements of the metallurgical industry for materials. Using centrifugal casting technology, the organizational structure of the casting is uniform, thereby improving its stability and durability under high temperature conditions. Especially in the manufacture of key equipment such as furnace bodies and roller shafts, centrifugal casting provides these parts with longer service life and higher working efficiency.

Industrial Centrifugal Casting also plays a vital role in the chemical industry. Many chemical equipment need to withstand corrosive media and extreme working conditions. The centrifugal casting technology can ensure the strength and corrosion resistance of the castings, especially when producing equipment involving high temperature and high pressure reactions. Centrifugal casting can ensure that the castings are free of pores and cracks, thereby improving the safety and reliability of the equipment. The alloy steel products produced by Xinghua Jinniu are widely used in chemical production lines, providing an ideal solution.

In addition, Industrial Centrifugal Casting is also widely used in heat treatment and new cement dry process conventional, waste incineration and other production lines. Centrifugal casting can provide these industries with extremely durable castings, especially those key components that need to withstand high temperatures and corrosive environments for a long time. Xinghua Jinniu has accumulated rich experience in the application of these fields, and the alloy steel castings produced can withstand extreme working conditions and ensure the efficient operation of the production line.

The advantages of Industrial Centrifugal Casting technology are not only reflected in the quality and durability of the castings, but also in improving production efficiency. Through the action of centrifugal force, the molten metal is evenly distributed in the casting mold, reducing pores and other casting defects and increasing the density of the material. This technology is widely used in heavy industries that require high-performance, high-precision parts.

English

English русский

русский Español

Español عربى

عربى