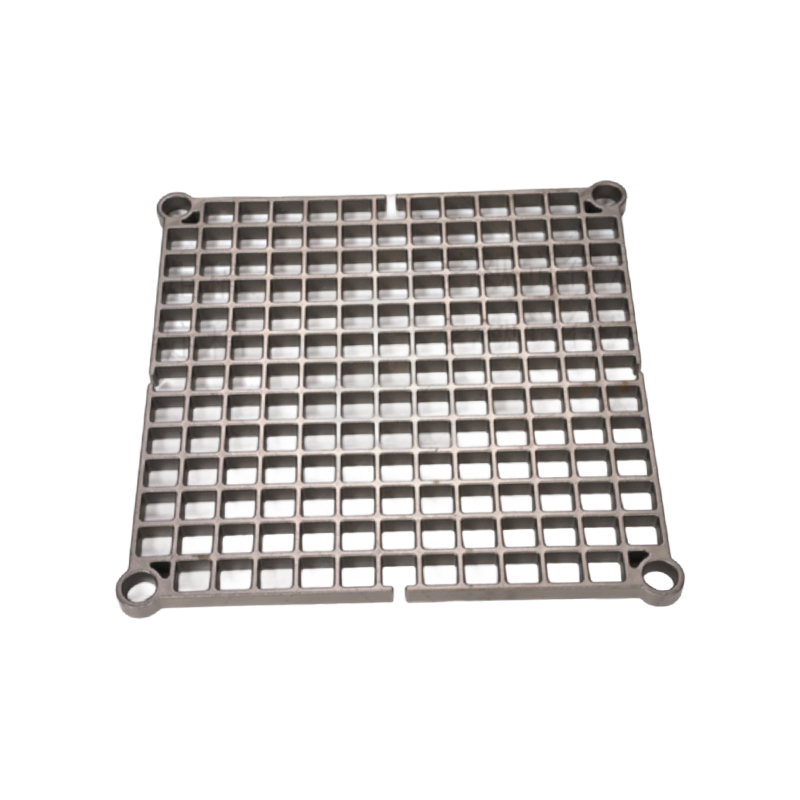

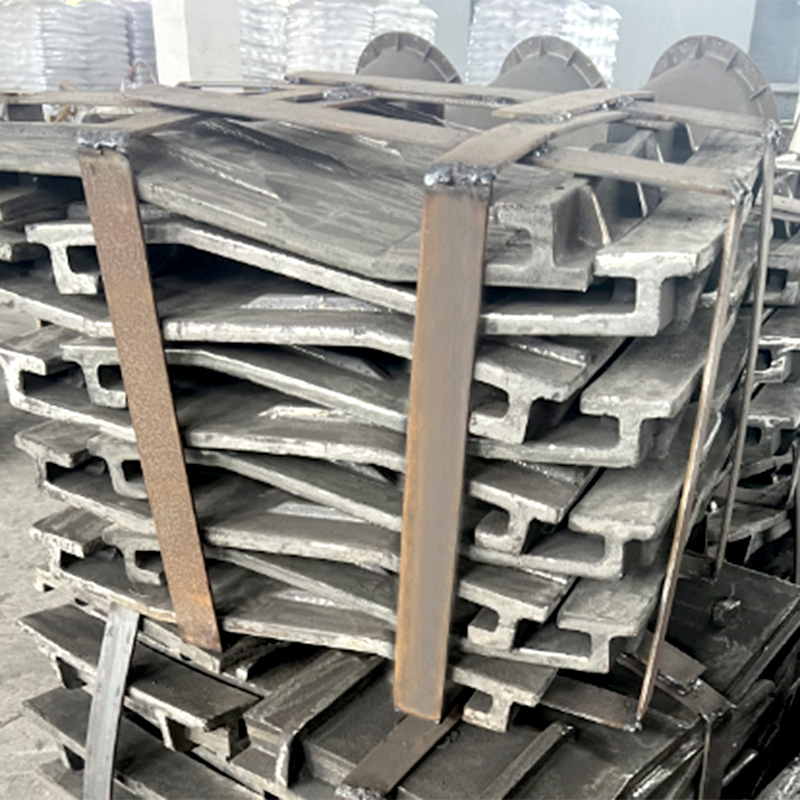

- The casting has high dimensional accuracy, low surface roughness, and is close to the level of lost foam casting. There is no need for traditional sand mixing, core making, molding and other processes and equipment. The process is simplified, mechanization and automation of production are easily achieved, lower investment in equipment and a small occupied area.

- The empty spaces and grooves that originally needed to be processed and formed can be cast directly. Casting cleaning is easy, machining is reduced, and manufacturability is high. There are virtually no restrictions on alloy types, casting sizes, and production volumes.

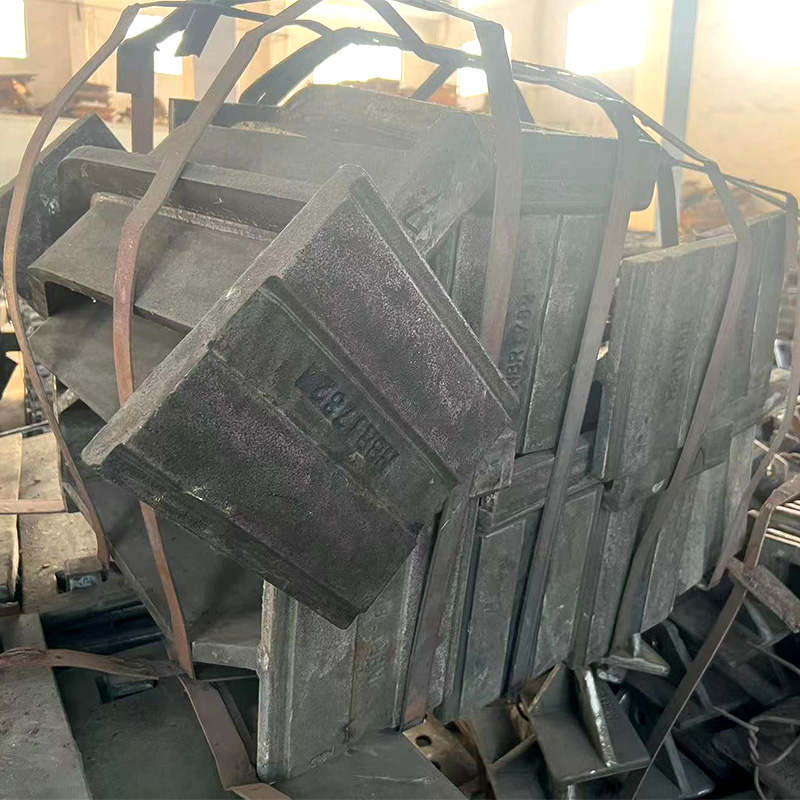

- Lost foam casting does not require core classification and placement, making it particularly suitable for complex geometries and traditional casting that is difficult to perform. The model buried in dry sand is used for lost foam casting, it is reusable, has less industrial waste, and significantly reduces costs. Lost foam casting has no burrs and flying edges, and cleaning time can be reduced by more than 80%.

Lost Foam Casting

Lost foam casting is a process in which a soluble mold is made, then coated with molten metal material, and finally the mold is dissolved or burned to obtain a casting. This method is suitable for metal parts with complex shapes, surface finish, and high precision. Lost foam casting is widely used in aerospace, automobile, machinery, art and other fields, and can meet high design standards and quality requirements.

View more-

In modern industrial manufacturing, precision and reliability during high-temperature processing are essential. Whether used in automotive components, aerospace...

READ MORE -

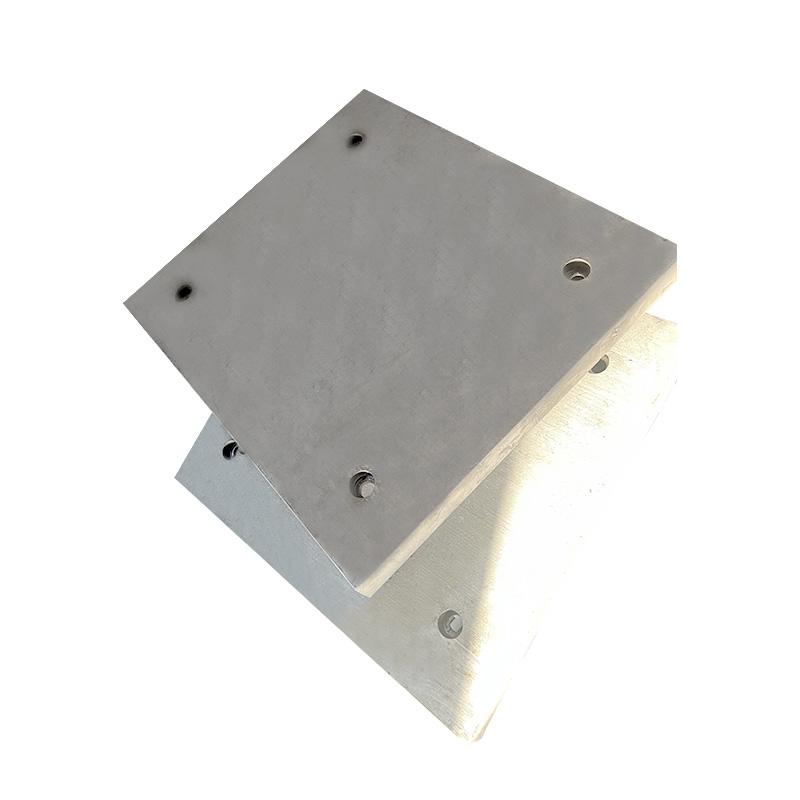

Heat Treatment Tray plays a pivotal role in achieving uniform heat distribution during various heat treatment processes, such as annealing, tempering, and quenc...

READ MORE -

Heat treatment trays are essential tools used in various industrial processes, especially in heat treatment applications for metals, ceramics, and other materia...

READ MORE -

Heat Treatment Tray is an essential piece of equipment used in various industries to withstand extreme temperatures during heat treatment processes. These trays...

READ MORE

Why is Lost Foam Casting Components so important in the production of complex-shaped castings?

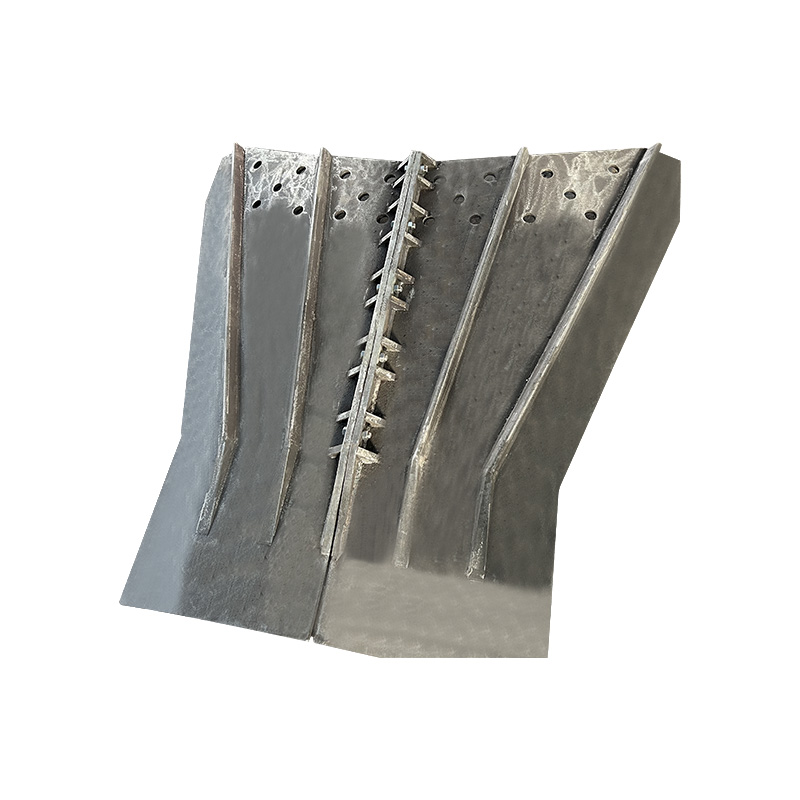

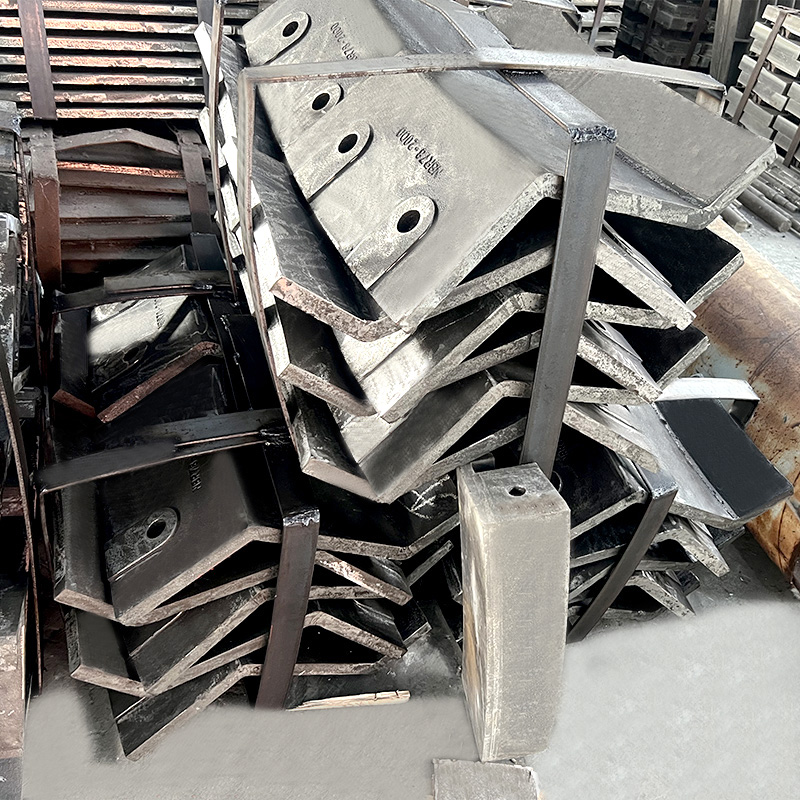

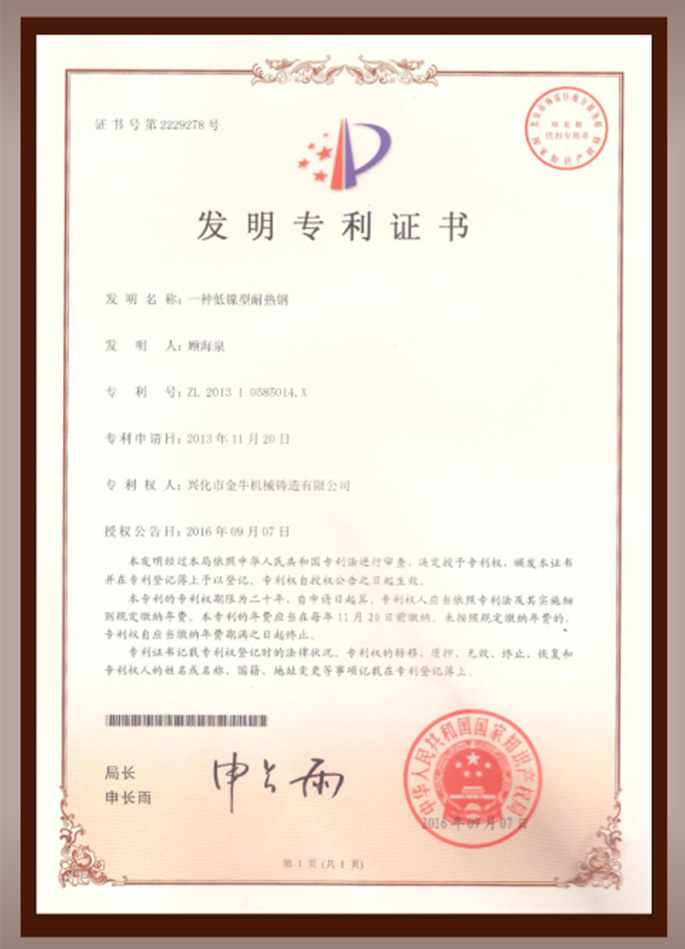

In the foundry industry, Lost Foam Casting Components have attracted much attention for their unique advantages in the production of complex-shaped castings. This casting technology can not only efficiently produce complex-shaped parts by injecting molten metal into a mold made of a soluble foam model, but also greatly improve the accuracy and surface quality of the castings. For companies like Xinghua Jinniu Machinery Manufacturing Co., Ltd. that focus on producing high-temperature, wear-resistant, and corrosion-resistant alloy steel products, Lost Foam Casting Components technology provides an ideal solution to meet the needs of various demanding applications.

When manufacturing complex-shaped castings, traditional casting methods often face some challenges, especially in the production of castings with fine details and complex structures. The application of Lost Foam Casting Components can break through these limitations because the process can directly cast almost any complex geometry with a foam model. The corrosion-resistant alloy steel components produced by Xinghua Jinniu often need to withstand high temperatures and high pressures. These components usually have complex geometric structures and are suitable for high-precision and complex shapes using lost wax casting technology.

Another important advantage of this process is that it can significantly reduce pores and cracks in castings. Through lost wax casting, the foam model is completely evaporated during the casting process, and the metal material can tightly fill every detail in the mold to ensure that there are no pores or cracks inside the casting. This is especially important for the high-strength alloy steel products produced by Xinghua Jinniu in the metallurgical and chemical industries, because these products usually need to maintain excellent performance and stability in harsh environments.

Lost Foam Casting Components technology also has high process flexibility and adapts to the requirements of many industries for the complexity of castings. For example, in the chemical industry, many equipment components need to have complex internal channels and small structures. The casting of these components using traditional methods often faces the problem of low production efficiency and high cost. By using lost wax casting technology, Xinghua Jinniu can efficiently produce components with complex shapes while maintaining high precision and high quality of production.

Lost Foam Casting Components is also critical for casting high-temperature corrosion-resistant alloys. These materials are often used in high-temperature working environments such as metallurgy, waste incineration and heat treatment equipment, requiring strong structural strength and high-temperature resistance. The use of lost wax casting method can achieve more accurate shapes and sizes during the casting process, thereby enhancing the durability and reliability of the castings.

Xinghua Jinniu Machinery Manufacturing Co., Ltd. widely uses Lost Foam Casting Components technology in the production of high-end alloy steel castings, meeting the needs of multiple industries such as metallurgy, chemical industry, and heat treatment. Through this advanced casting process, we provide customers with more complex and high-performance castings to help all walks of life cope with increasingly complex production requirements.

Lost Foam Casting Components not only improves casting accuracy and surface quality, but also greatly expands the application range of casting technology. It is undoubtedly one of the most ideal casting methods for industries that require high-performance, complex-shaped castings, especially in the production of high-strength alloy steel parts. Xinghua Jinniu will continue to be committed to technological innovation in this field and provide customers with the most reliable casting solutions.

English

English русский

русский Español

Español عربى

عربى