- The sand casting has good rigidity, which is conducive to the expansion of graphite during the solidification process of cast iron due to the high strength of the sand mold in the early stage of casting. It can effectively eliminate the shrinkage and porosity of the workpiece.

- In the foundry industry, polystyrene foam molding is widely used, and self-hardening sand molding with rosin resin is also used. When the liquid metal is poured into the resin sand mold, the foam pattern is a liquid metal with high diffusion and high pressure.

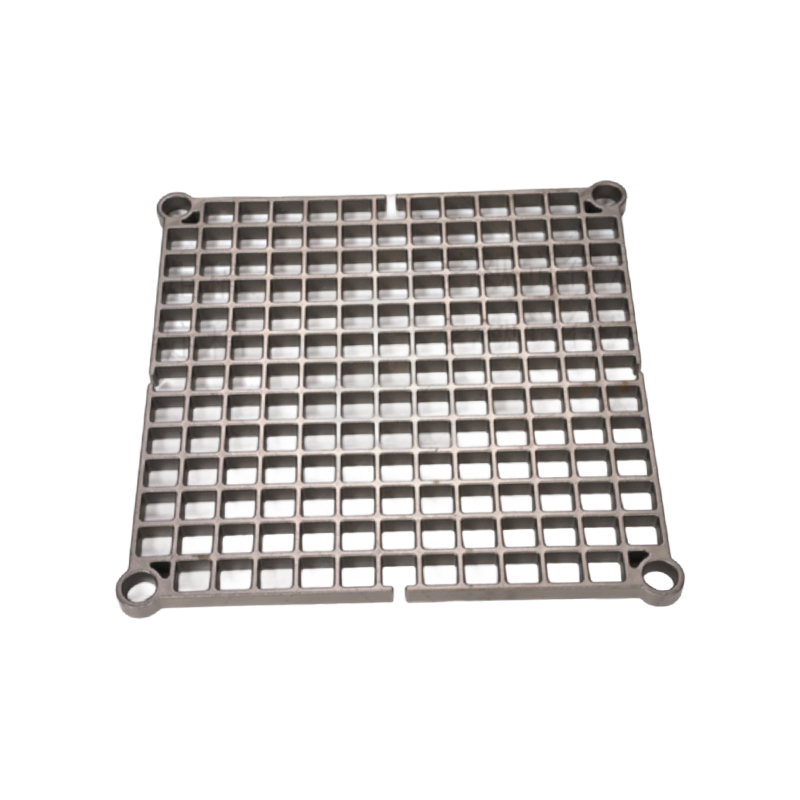

Resin Sand Casting

Resin sand casting is a casting process that uses resin sand as the mold material. Its advantages are simple process and easy operation. Compared with other casting methods, the resin sand molding process has a high molding speed and does not require drying and molding, which reduces the deformation of castings caused by firing and molding. At the same time, resin sand has good fluidity, does not require tamping and tightening, which reduces the damage and deformation of the core box, and greatly shortens the production cycle and delivery cycle of castings. This process is widely used in such fields as automobile, machinery, aerospace and art, meeting the needs of complex molds and high quality standards.

View more-

In modern industrial manufacturing, precision and reliability during high-temperature processing are essential. Whether used in automotive components, aerospace...

READ MORE -

Heat Treatment Tray plays a pivotal role in achieving uniform heat distribution during various heat treatment processes, such as annealing, tempering, and quenc...

READ MORE -

Heat treatment trays are essential tools used in various industrial processes, especially in heat treatment applications for metals, ceramics, and other materia...

READ MORE -

Heat Treatment Tray is an essential piece of equipment used in various industries to withstand extreme temperatures during heat treatment processes. These trays...

READ MORE

What are the applications of Resin Sand Casting Solutions in different industrial fields?

Resin Sand Casting Solutions is an advanced casting technology that is widely used in multiple industries, especially in the production of castings that require high strength, wear resistance, corrosion resistance and high temperature tolerance. With the continuous development of technology, this casting method has become an indispensable part of many heavy industries. Xinghua Jinniu Machinery Manufacturing Co., Ltd., with its excellent alloy steel production capabilities, uses Resin Sand Casting Solutions to provide high-quality casting products for multiple industries to meet the stringent requirements of different fields.

In the metallurgical industry, Resin Sand Casting Solutions is widely used to produce high-temperature and wear-resistant castings with its precise casting process and excellent metal fluidity. These castings are often used in the manufacture of high-strength equipment, such as furnace bodies, rollers and other key components. In metallurgical production lines, these castings need to withstand extreme high temperature and high pressure environments, and Resin Sand Casting Solutions castings can ensure their stability and reliability under extreme conditions. Xinghua Jinniu's technical advantages in this field enable its products to work stably for a long time, reduce equipment failure rates and extend service life.

In the chemical industry, resin sand casting is particularly widely used. Many chemical equipment need to operate for a long time in a corrosive environment, and Resin Sand Casting Solutions provides an ideal solution for this. By optimizing the resin sand formula and casting process, the corrosion resistance and service life of the castings can be effectively improved. Xinghua Jinniu has accumulated rich experience in the research and development of corrosion-resistant alloy steel castings. The castings it produces can be used to manufacture chemical equipment such as reactors, pump bodies, valves, etc., to ensure their efficient operation in harsh environments.

In the heat treatment industry, Resin Sand Casting Solutions also plays an important role. Many heat treatment equipment needs to withstand high temperatures and strong wear, especially key components such as heating furnaces and heat exchangers. Resin sand casting ensures the high density and strength of the castings by optimizing the casting process, enabling it to maintain excellent performance under high temperatures and extreme working conditions. The high-temperature resistant alloy steel castings produced by Xinghua Jinniu are widely used in various heat treatment production lines, meeting the industry's demand for durability and efficiency of castings.

In waste incineration and new cement dry process conventional production lines, Resin Sand Casting Solutions also plays an important role. With increasingly stringent environmental protection requirements, these industries have put forward higher requirements for the high temperature resistance and corrosion resistance of equipment. Resin sand casting can produce castings that can withstand high temperatures and highly corrosive gases, ensuring efficient operation and long-term stability of equipment. Xinghua Jinniu uses advanced resin sand casting technology to provide these industries with casting solutions with excellent durability.

Through Resin Sand Casting Solutions, Xinghua Jinniu Machinery Manufacturing Co., Ltd. provides high-performance, high-quality castings in multiple industries, helping customers improve production efficiency, reduce maintenance costs, and extend the service life of equipment. Whether in the fields of metallurgy, chemical industry or heat treatment, Xinghua Jinniu's resin sand casting solutions can meet stringent industrial needs and promote the continuous development of various industries.

English

English русский

русский Español

Español عربى

عربى