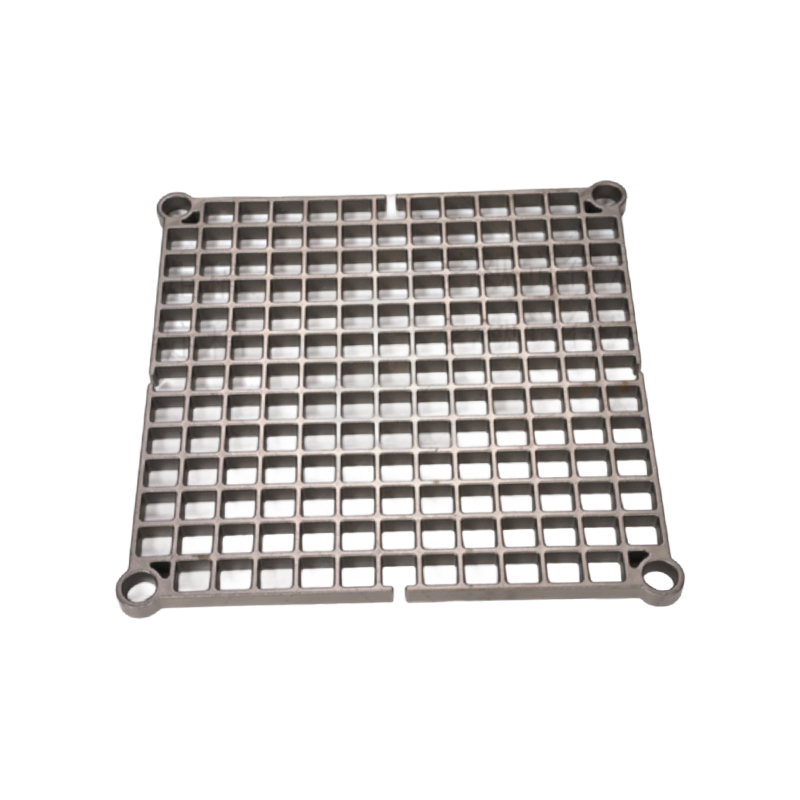

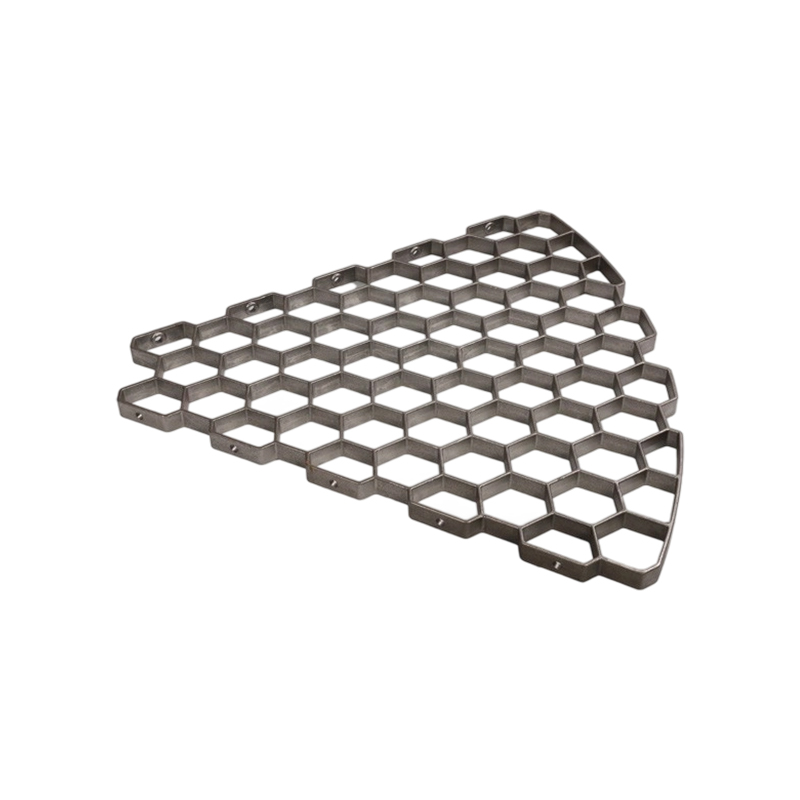

- Compared with traditional lost wax casting methods such as liquid glass, castings produced using quartz sol precision investment casting have finer surface roughness, smaller machining allowances, and can even achieve machining without cutting.

- Silica wax precision casting has a wide casting range and complex product structure. It can cast irregular-shaped parts that cannot be produced by traditional sand molds, foam molds and other processes, as well as castings with more complex structures.

- There are many casting materials, mainly stainless steel, alloy steel, carbon steel, copper alloy, aluminum alloy, etc.

Silica Sol Lost Wax Precision Casting

Silica sol precision investment casting is a high-precision casting technology that uses silica sol as a casting material to produce complex-shaped metal parts through the lost wax method. This process has surface finish and dimensional accuracy, and is widely used in metallurgy, chemical industry, heat treatment, new cement dry drying line, granule, waste incineration and other fields. It is suitable for high-temperature and high-intensity conditions, and meets strict quality and safety standards.

View more-

In modern industrial manufacturing, precision and reliability during high-temperature processing are essential. Whether used in automotive components, aerospace...

READ MORE -

Heat Treatment Tray plays a pivotal role in achieving uniform heat distribution during various heat treatment processes, such as annealing, tempering, and quenc...

READ MORE -

Heat treatment trays are essential tools used in various industrial processes, especially in heat treatment applications for metals, ceramics, and other materia...

READ MORE -

Heat Treatment Tray is an essential piece of equipment used in various industries to withstand extreme temperatures during heat treatment processes. These trays...

READ MORE

What Makes Precision Lost Wax Casting the Gold Standard for Complex Metal Parts?

In the world of metal manufacturing, precision and complexity often collide with the limitations of traditional casting methods. Yet, one technique consistently rises above the rest for crafting intricate, high-performance components: Precision Lost Wax Casting. This centuries-old process, refined with modern innovations, has become the gold standard for industries demanding flawless geometries, ultra-thin walls, and unmatched material integrity.

The Science of Perfection

Precision Lost Wax Casting begins with a meticulously designed wax pattern, replicated from a master model. This pattern is coated with layers of ceramic slurry to form a heat-resistant shell. Once cured, the wax is melted away, leaving a cavity that mirrors the original design. Molten metal is then poured into the cavity, solidifying into a near-net-shape part with exceptional dimensional accuracy. The process eliminates seams and minimizes post-processing, making it ideal for components requiring tight tolerances—often below 0.1mm—and intricate internal features.

For industries like aerospace and medical implants, where failure is not an option, this method ensures reliability. Turbine blades with cooling channels, surgical tools with micro-scale details, and fuel injection nozzles with complex geometries all rely on the precision achievable only through lost wax casting.

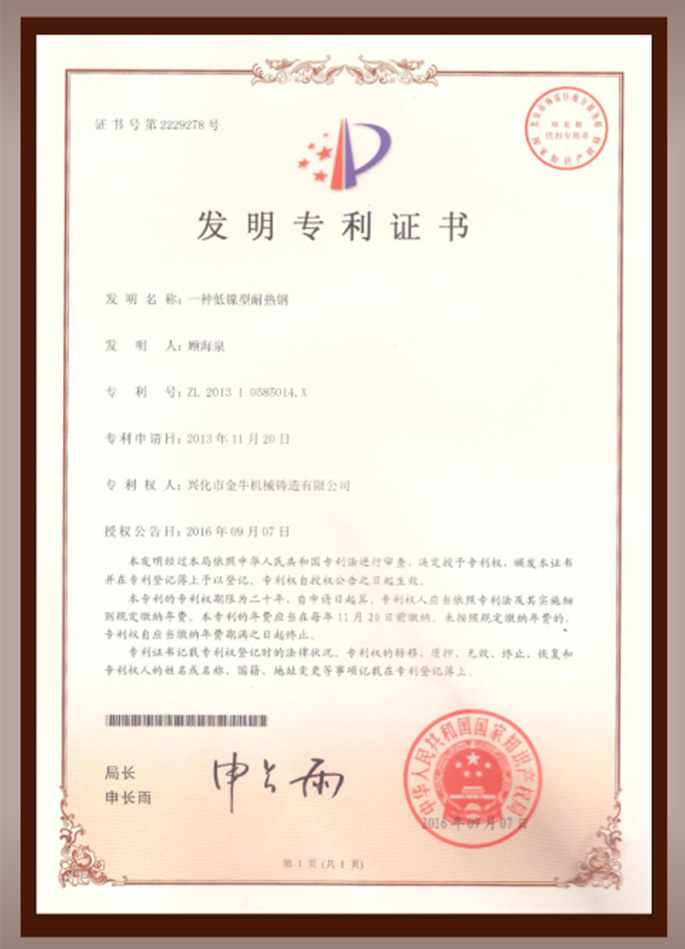

Xinghua Jinniu: Engineering Excellence in Every Cast

At Xinghua Jinniu Machinery Manufacturing Co., Ltd., we’ve harnessed this technology to push the boundaries of material performance. Specializing in heat-resistant, wear-resistant, and corrosion-resistant alloys, our expertise lies in creating components that endure extreme environments. From metallurgy furnaces to chemical reactors, our super-strong alloy steel products are engineered to withstand temperatures exceeding 1200°C, corrosive chemicals, and relentless abrasion.

One standout innovation is our nickel-saving alloys, developed to reduce material costs without compromising strength. These alloys are now integral to modern cement production lines, pelletizing systems, and waste incineration plants, where durability directly impacts operational efficiency. By combining advanced heat-resistant steel materials with precision casting, we deliver parts that outlast conventional alternatives by up to 300%.

Bridging Tradition with Technology

While the core principles of lost wax casting remain unchanged, Xinghua Jinniu integrates cutting-edge advancements to elevate outcomes. For example, 3D-printed wax patterns enable rapid prototyping and customization, slashing lead times for clients in fast-paced industries like automotive and energy. Digital simulations optimize mold designs, reducing trial-and-error and ensuring first-pass success.

Why Choose Xinghua Jinniu?

For over two decades, we’ve partnered with global leaders to solve their most challenging engineering problems. Whether it’s a custom heat-resistant grate for a garbage incineration line or a corrosion-resistant valve for a chemical plant, our precision-cast components are trusted to perform under pressure.

English

English русский

русский Español

Español عربى

عربى